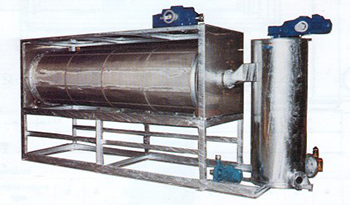

Dynamic Thickener

The dynamic thickener is a rotating drum machinery, which is able to thicken the sludge not thickened, till arriving a concentration of 10 – 12%.

The sludge, conditioned with chemical reagents (polyectrolyte) is introduced in the mixer, equipped with variable rotation stirrers.

The mixer is positioned outside the thickener and is used to optimize the coagulant efficacy and to reduce the consumption of the product.

Subsequently, the flocculated sludge is conveyed inside the thickening drum.

The flocculated sludge is drained by the cloth, which envelops completely the drum.

The water contained in the sludge, passing through the cloth, is collected in the bottom tank and subsequently discharge.

In the main time, the sludge is conveyed outside the drum, by the inside screw, which makes also a mechanical retention, to increase the times of sludge staying on the cloth.

The drained and thickened sludge is discharged outside by the discharge outlet, to which is possible to couple a collection hopper, or is directly discharged in a containment tank, or in a belt filter press.

To increase the drainage efficacy, the cloth is continuously washed by a bar of spraying nozzle, which covers all the length of the drum, with water having a pressure of about 3 bar.

The water used for the washing can be indifferently clean or dirty.

The special type of cloth allows to reach a solid retention till 98% on the entrance sludge.

STRENGHTS:

- efficiency sludge pre-thickening

- high efficiency due to the internal screw

- construction in stainless steel