Heat Recovery Maia

Equipment fir the recovery of the vapor phase dissipated in the tank

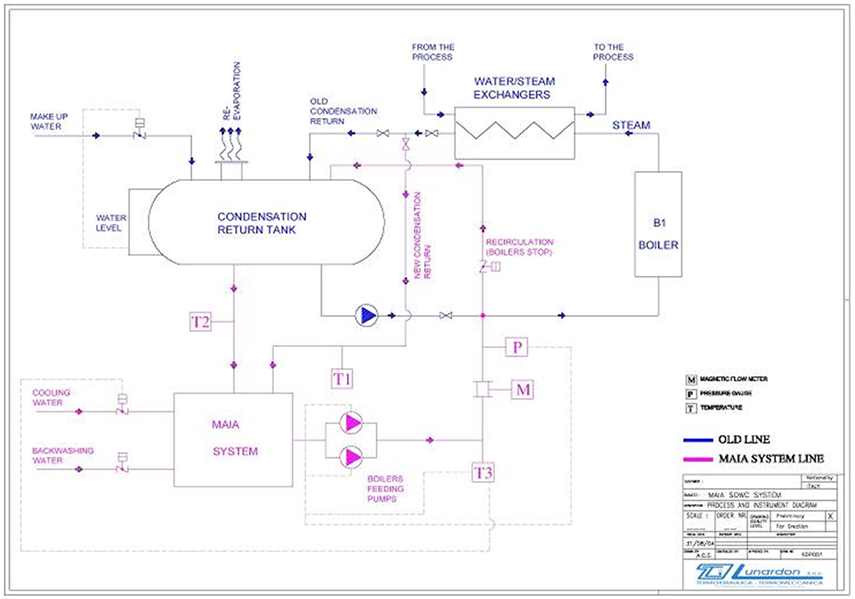

PRINCIPLE OF OPERATION

The heat recovery MAIA is able to recover the total steam generated with the portioning of condensate upstream of the tank.

It carries out a heat exchange and mixing between the condensate normally warehoused in the tank ( thermal flywheel system) and portion of liquid re-evaporated in the return line.

Recovery is made of the thermal type, by the recovery of the energy of condensation and thanks to recovery demineralized water.

HYDRAULIC CHARACTERISTICS

- RECOVERY: recirculation circuit to the condensate tank

- CALLING: circuit of direct power supply to the suction pumps of the generator

- EMERGENCY: safety circuit with by-pass the recovery of thermal cycle

FUNCTIONAL FEATURES

- Circulation pumps regulated by inverter, to reduce consumption and to optimize the flow.

- Continuous monitoring of the temperature valves, pressure and scope of the various flows circulating, quantification of recoveries.

Thermal recovery can reach 10-12% of energy requirements of the generator.

Recovery depends on the conditions of use of the thermal cycle and the general layout consolidation.

The mass of water recovered as the condensed phase thanks to the heat exchange realized in MAIA, may reach 8% in favor of the softening system.